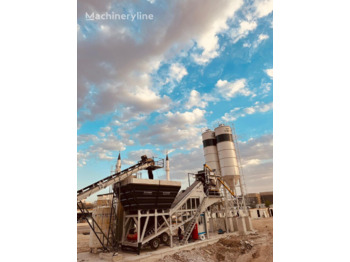

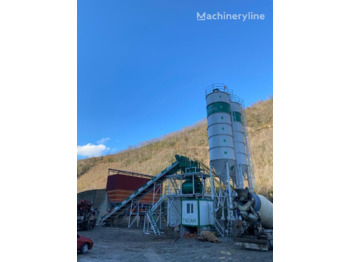

New Concrete plant Plusmix 100m³/hour Stationary Concrete Plant -BETONYY ZAV

Published: 2mo 14d

Published: 2mo 14d

Do you need shipping?

AGGREGATE BUNKER

Volume : 4x25 = 100m3

Number of compartments : 4 compartments 4 pcs. dosing cover

Plate thickness : Cast hoppers 7 mm top covers 6 mm unloading cover 12 mm

Vibrator : 3 pcs. 300/3 350-400 kg pulse KEM-P

Air Installation : Made of 1’’ PVC pipe, resistant to pressure, 8 pcs. Italian valve 2 pcs. air preparer are available.

Closing of bunker top with painted trapeze plate

AGGREGATE WEIGHING BELT

Size : 1000x 12.000 mm

Chassis Structure : Made of NPU profile, designed for maximum resistance to impact and bending.

Motor : Gamak 15 kw

Reducer : Dişsan DG 2-225

Belt rubber : 4 layered EP125

Bearings : with SNH series lubricator

Safety systems : Emergency stop button

Loadcell : 4 pcs. 5000kg KELLY brand

WEIGHING BELT GENERAL PROPERTIES

• With 2.5% error margin in aggregate weighing, precision has been increased to maximum level.

• There are 2 safety hangers for protecting weighing belt in bolt or load cell ruptures that may happen in time during aggregate weighing

• Equipped with safety measures such as emergency stop.

• Designed for easier loading compared to traditional loading methods.

• Made of steel material as 4 compartments, each being 25m3 with a total of 100m3 aggregate storage capacity.

• Each aggregate compartment has 4 unloading (dosing) cover. Unloading covers are opened and closed by pneumatic pistons. There are a total of 8 pneumatic pistons in the aggregate bunker.

• The Aggregate Weighing Bunker with 5.000 kg weighing capacity uses 4 pcs. of KELLY load-cells.

• Width:1000 mm., Length:12.000 mm. aggregate weighing belt consists of 4 layered EP125 belt in TS 542 standards. Belt drive power is 22 Kw.

• Driving drum is covered with rubber to prevent belt slipping.

• There are 2 pcs. of electrical vibrators in the front partition of the bunker.

MIXER FEEDING BELT

SIZE : 1000X28.000 MM

MOTOR : GAMAK brand 30S kw.

REDUCER: Dişsan DG 2-250 locked (prevents the material on the belt to go back during power loss)

DRUMS: Covered with rubber to prevent slipping of belt.

BELT RUBBER: EP160 BANTSAN brand.

BEARINGS: SNH series lubricator

PLATFORM: Double sided walkway and job safety compatible railing.

SAFETY SYSTEM: Emergency stop button-belt slip switch.(optional)

MIXER GROUP

Main unit of the mobile concrete plant. All equipment is mounted on the trailer chassis and the system is made fully mobile. Compared to stationary concrete plant, mobile concrete plant has many advantages. To list the main ones;

- Low set up costs. There is no need for large foundation concrete bases for the installation of a mobile concrete plant. Only the basic concrete pedestal for the cement silo should be constructed. This way, set up costs are minimized.

- Easy set up and commissioning. While the installation of the stationary concrete plant lasts 10 to 15 days, the installation of the mobile plant lasts 2 days and 1 day for each welded type of cement silo installation and 3 days for the bolted type cement silo is enough.

- Easy maintenance and low maintenance costs. Since all equipment is compactly mounted on the trailer chassis, the mechanisms can be disassembled and maintained or replaced in a very short period of time.

PLUSMIX SINGLE SHAFT MIXER GENERAL SPECIFICATIONS

. Double-spiral arm design ensures obtaining desired homogeneous mixture in the shortest time.

Special GAMAK electrical motor is driven by 37*2 kW YILMAZ reducer.

Thanks to the spiral mixer arms which fully sweep the inner surface of the mixer, obtaining concrete at the desired quality is possible. There are 2 group mixers and 2 panel scrappers available as right helix and left helix. Liners are 14-16% manganese cast and palettes are produced from Ni-Hard4 cast material.

Fast and easy unloading.

Max. 110 mm sized aggregate mixing capacity.

In the event of a power failure, there is a quick coupling and lever on the unit to manually open the hydraulic discharge cover and the lid to unload the concrete mixture in the mixer.

Low operating and maintenance costs, fast and easy to use mixer shafts and seals.

Chain drive system, easy to service and maintenance.

The inner wear liner plates are easy to replace.

Operator faults are prevented by using ILC (Italian) Automatic centralized lubrication system. Bearings are lubricated with our time-controlled lubrication system to prevent hazards such as oil leaking or heating, winding.

MAIN CHASSIS AND FRAME STRUCTURE GENERAL PROPERTIES

• Chassis body is made of NPU profiles with resistance to all vibrations and torsions.

• Railings, walkways and platforms for the repair works at the mixer area are made in CE standards.

• Smoothing process is applied on all surfaces, primer paint is made and painted with a final layer of industrial type paint.

CONCRETE MIXER TOP UNIT

Aggregate Waiting Chamber : 1 pc.

Capacity : 2,5 m3

Primer : Yes

Valve : Pneumatic driven Butterfly Valve

Vibrator : 200/3

Cement Weighing Chamber : 1 pc.

Weighing Capacity : 1000 KG

Loadcell : 3x1000 KG (KELİ)

Pneumatic Valve : V1-FS300S DIAMETER: 300mm

Valve Driver : CP 101

Vibrator : 1 pc. 100/3

Water Weighing Chamber : 1 pc.

Weighing Capacity : 600 KG

Loadcell : 2x1.000 KG (KELİ)

Pneumatic Valve : V1-FS150S Diameter: 150mm

Valve Driver : CP 101

Additive Weighing Chamber : 1 pc.

Weighing Capacity : 50 KG

Loadcell : 100 KG S Type (KELİ)

Pneumatic Valve : 1’’ Actuator Spherical

Air Compressor: 1 pc.

Brand : Akkomp

Capacity : 1210 lt/min air flow

Tank Volume : 700 lt

Motor Power : 7,5 kW 10 Hp

Operator Cabin :

Made of 2 mm. thick St-44 structural steel material.

40 mm. thick glasswool is used between the plate panels to prevent heat transfer.

Control cabin dimensions Width:2350mm Length:3500mm Height:2200mm

AUTOMATION SYSTEM

PLUSMİX brand concrete power plant automation systems are used in PLUSMIX concrete power plants. All system control is provided by Kartal or lion (display control panel ) designed by Turkish engineers. The PLC modules used in system control operate only as interfaces. The indicators used in weight measurement are high-tech and small-size, fast, responsive and accurate. The key materials used in the MCC control panel are SIEMENS brand. All control cables on the control panel are labeled on the ports. In this way, fault detection and monitoring can be done more easily.

Concrete production is completely automated through the computer. If necessary, the system can be interfered with using a mouse from the SCADA screen. The system in the SCADA program can be designed according to the characteristics and type of the official plant.

In addition to fast and reliable operation of the BETOSYSTEM SCADA program, it is also possible to access statistical and detailed production information. All reports made on the basis of the most preferred detailed production, prescription, customer, carrier and material can be obtained in detail from the computer screen or printer within the desired date range. In addition, if desired, the report can be designed with a custom reporting option. Our automation system guarantees accurate and accurate production as well as continuous and reliable operation with all high quality equipment

SCADA PROGRAM

Computerized control system and control (SCADA) system

PLUSMİX; concrete production SCADA program ( Beto system ) is a process control program specially developed for concrete plants because the indicator, PLC, is a much faster communication between PC. The EAGLE indicator and control device, which is developed only for concrete plants, contains all the equipment required for the control of the plant. With its electronic buttons and Universal visualizations on Eagle, it provides ease of use to all operators around the world. All production is monitored visually through SCADA program, intervene if necessary, order, recipe, parameters, inventory acceptance, failure tracking and reporting details of the production can be taken. It is extremely easy to use and can be monitored remotely if desired. All the records of the production can be transferred to a specified PC continuously.

Do you need shipping?

Get a shipping quote

Do you need shipping?

Get a shipping quote